How a 19th-century invention still feeds America — and why Canco seamers are still on the line.

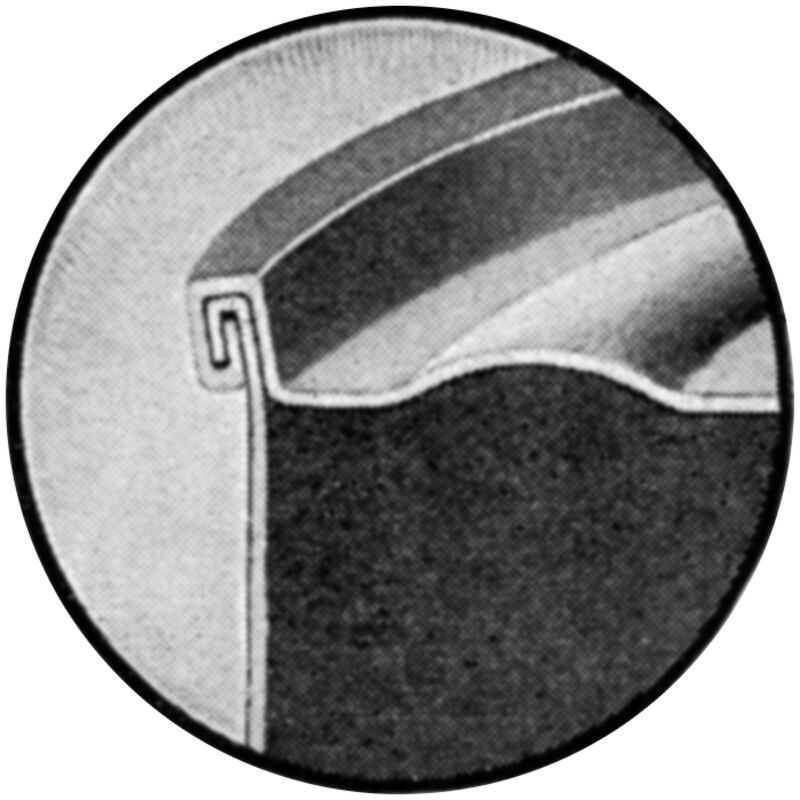

In 1888, a German-born New Yorker named Max Ams solved a problem that had plagued the canning industry for decades. His invention — the double seam — eliminated the need for lead solder in sealing cans, replacing a toxic and unreliable process with a mechanical one. Five layers of metal, interlocked and compressed by rollers into a hermetic seal. No heat. No chemicals. Just geometry and force.

The double seam is still how every can on every shelf in every grocery store in America gets sealed. And the machines that create those seams have a lineage worth knowing, especially if you're running a food packing line or thinking about starting one.

What a Double Seam Actually Is

Before we talk about machines, it helps to understand what they're doing.

When a can seamer closes a lid onto a can body, it creates a joint from five interlocking layers of metal — three from the lid, two from the body. The first operation roller curls the lid edge under the body flange. The second operation roller compresses the whole assembly tight. A rubber-based sealing compound applied inside the lid's curl radius creates the actual hermetic barrier.

Get it right and the contents are safe from contamination for years. Canned food recovered from a steamboat that sank in the Missouri River in 1865 was tested over a century later and found to be still safe to eat. That's the double seam doing its job.

Get it wrong — even slightly — and the consequences range from spoilage to contamination to product recalls. Seam integrity is the single most critical quality control point on a canning line. Everything else downstream depends on this one mechanical joint holding.

Where These Machines Come From

The American Can Company — Canco to the people who ran the machines — was incorporated in 1901 through the merger of 123 small can manufacturers. But the part of the story that matters to food processors isn't the corporate history. It's what happened inside one building in upstate New York.

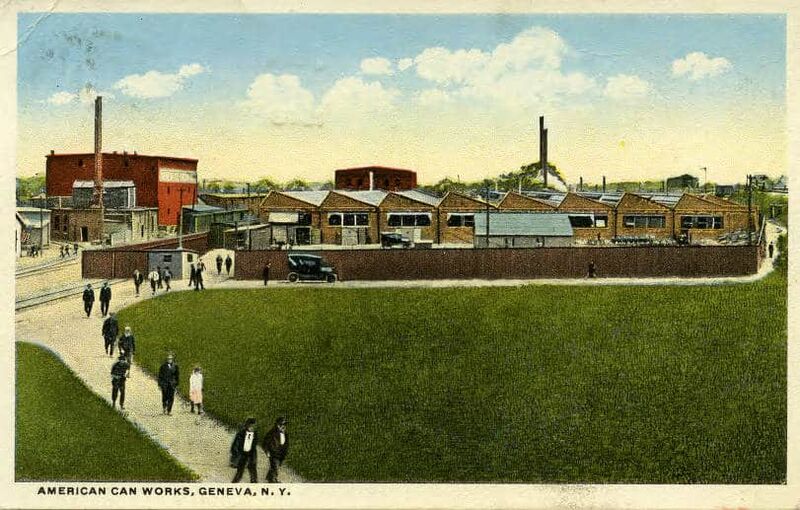

In 1923, American Can converted its factory in Geneva, New York into a dedicated machine shop for designing and manufacturing can seaming equipment. By 1966, that single facility covered 250,000 square feet, employed 875 workers, and was producing $19 million worth of machinery a year. The machines they built — the 06, the 08, and their variations — became the workhorses of the American food packing industry.

The company eventually sold off its entire U.S. packaging division in 1986 and renamed itself Primerica, chasing financial services. The corporate entity that made the machines is long gone.

The machines are not.

Why the 06 and the 08 Endure

If you ask someone why they're still running a Canco 06 or 08, you'll hear variations of the same answer: because it still works.

That's not nostalgia. These are machines built from cast iron and heavy-gauge steel, driven by gears and cams rather than servos and circuit boards. You can turn a seaming head by hand. You can diagnose most problems with your eyes, your ears, and a set of feeler gauges. When something drifts, the adjustment is physical — shims, a wrench, observation. Not a software update.

The Canco 06 handles can diameters from 202 to 404, covering everything from small spice tins to standard food cans. It runs up to 60 cans per minute with a single operator. The 08 takes the larger sizes, from 307 up to 603 — the big #10 food service cans that restaurants and institutions rely on — at 25 to 40 cans per minute depending on size. Both run atmospheric, vacuum, or steam-flow seaming depending on configuration, and both accept a wide range of can heights with change parts.

What keeps these machines in service isn't just the build quality. It's the fact that every working part is accessible and replaceable. Chucks, rolls, cam followers, lifter plates, feed chains, separator knives — these are all serviceable components with known specifications. A library of original manuals still exists. The knowledge base for setting up and troubleshooting these seamers runs deep in the industry, passed from one generation of mechanics to the next.

Built for the Middle

New can seaming equipment is expensive. Multi-head high-speed seamers from major OEMs can run well into six figures. For a large beverage company, that's a line item. For a regional salsa maker, a family spice company, a small-batch coffee roaster, or a startup putting its first product into cans, it can be the difference between launching and waiting.

A rebuilt Canco 06 or 08, properly tooled for the right can size and tested to seam specification, produces the same hermetic double seam as equipment costing many times more. The throughput is lower — you're not running 400 cans a minute. But for operations running a few thousand cans a day, a single operator and a reliable seamer covers a remarkable range of production needs.

There's also the matter of what happens when something breaks. On a Canco, you replace the part. These machines were designed in an era when equipment was expected to be maintained indefinitely, not replaced on a depreciation schedule. Compare that to a modern seamer that requires a factory technician, proprietary diagnostic software, or imported components with lead times measured in months. For a small processor who can't afford a day of downtime during peak season, repairability isn't abstract. It's the most practical consideration there is.

The Rebuild

Our appreciation for Canco seamers came about the old fashioned way — by tearing them apart and putting them back together. Before we rebuilt them we ran them in a coffee line. That experience gives us first-hand knowledge in the food packing industry that you can't get from a parts catalog.

The rebuild process has been refined over 20 years. Each machine gets stripped to bare metal. The hardest working parts go through an ultrasonic cleaner to remove grease and grime, then get wire brushed and inspected for wear and damage. Worn components get replaced. Every machine gets a brand new motor, set up for 3-phase 230V or 460V depending on the client's needs. Parts go back in, appropriately oiled and greased. We set the seaming height to the client's specification, run 100-200 of their cans and ends through the machine to verify timing and can handling, and set seams to their supplied specs.

The machine lands on a sturdy pallet, bolted down for shipping. Our rebuilds ship with a copy of the original manual and are sold with warranty.

It's not complicated. It's just thorough. And after hundreds of rebuilds, we know where these machines wear, what fails first, and what never fails at all.

What the History Got Right

The machines survive. They outlast the company that made them by decades. They get rebuilt by people who learned the equipment from the inside out, and they continue to serve the exact segment of the market that the big companies stopped paying attention to — small and mid-sized food processors who need reliability, repairability, and a cost of entry that doesn't require venture capital.

The Canco 06 and 08 aren't museum pieces. They're sealing cans of coffee and spices and vegetables and pet food right now, in facilities across the country, operated by people who chose function over flash and were rewarded for it.

That's the thing about a well-made machine. It doesn't care who owns the brand name. It just does the work.

Sullivan Trading Co. sells, rebuilds, and services Canco seamers — 06s, 08s, and more. We also carry parts, change parts, and original manual reprints. Based in [LOCATION]. Call [PHONE] or visit our shop.